Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

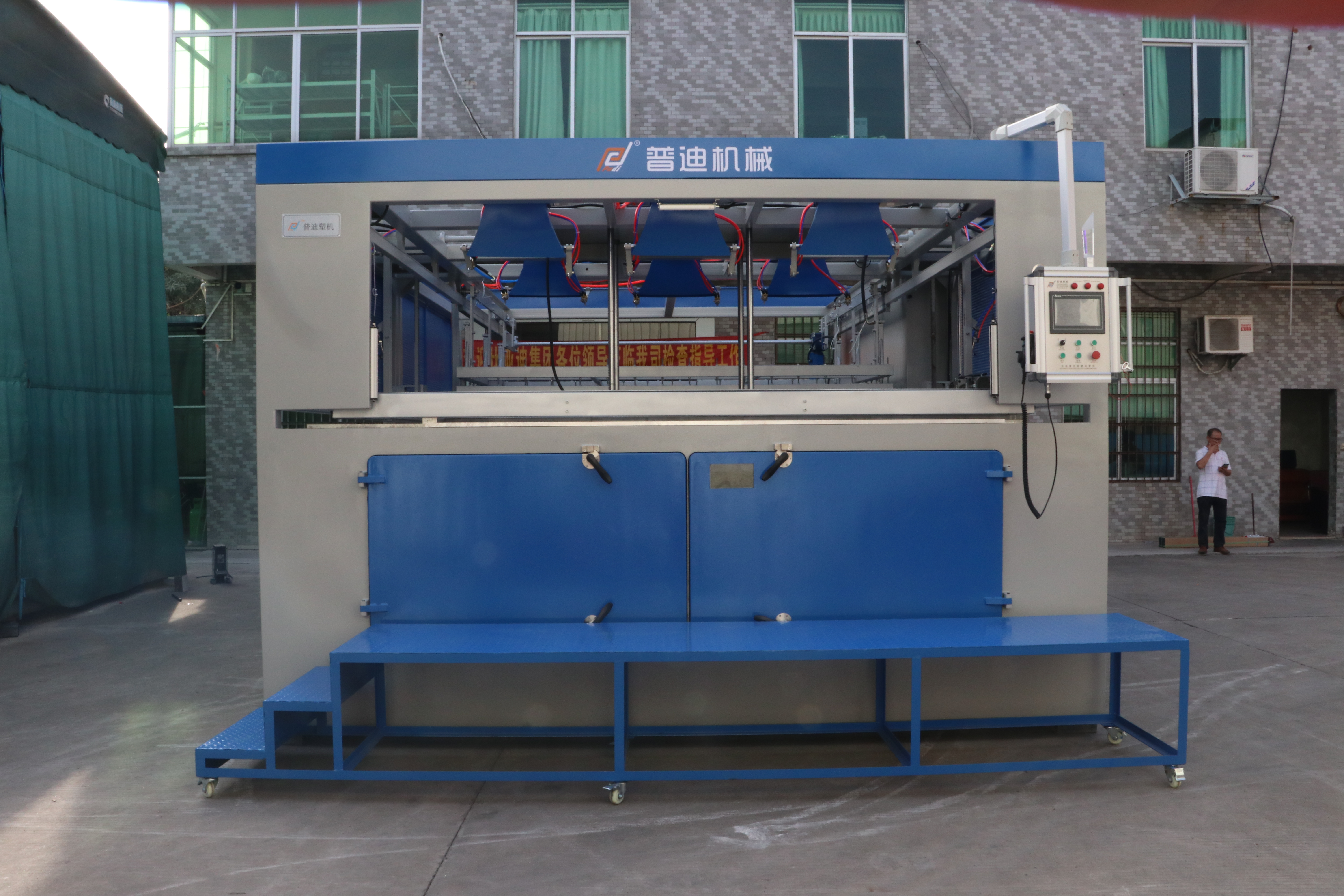

The automotive battery over and battery box vacuum forming machine can be heated evenly with the upgrade S pipe, which greatly improves the heating speed. The servo motor can make the demoulding stable and accurate, so that it can make good automobile battery cover and battery box with high efficiency. We can also support ODM service, and if you meet any problem in the future, you can also contact with us, we will try our best to solve it.

Even Heating:

This automobile battery cover and battery box vacuum forming machine is designed for even heating, making it ideal for mass production of battery covers and boxes. The machine is equipped with advanced technology to ensure uniform heating and accurate temperature control. It is easy to use, with a simple and intuitive interface. The machine is also highly efficient, allowing you to quickly and easily produce large quantities of battery covers and boxes. With its even heating and efficient operation, it can satisfy your all needs in production.

ODM Service:

It features a high efficiency and precise forming technology, and is able to produce parts with high accuracy and consistency. It is suitable for a wide range of materials, and can be used to produce complex shapes with a minimum of manual labor. We are from factory, so we accept the ODM service, whatever how machine that you want to make, we will all meet your satisfaction, and we will also do the after-sale service at irregular period, welcome to make advice that we need to improve.

Product Parameter:

|

Maximum Wellhead Size |

2600mm*1600mm |

|

Forming Depth |

500 mm |

|

Applicable Material Thickness |

1-10mm |

|

Main Switch |

three-phase five-wire 380V±15V, 50Hz |

|

Heating Power |

Upper Furnace: 128kw; Lower Furnace: 128kw; |

|

Total Power |

280kw (subject to actual conditions, normal use is between 50-70%) |

|

Mold Forming Method |

Concave-convex molding (one-shot molding) |

|

Electric Furnace Power |

Frequency Conversion Motor Drive |

|

Die Power |

Servo Motor (both upper and lower mold tables are driven by servo) |

|

Cooling Form |

Powerful Fan |

|

Heating Unit |

fast medium-wave infrared heating tube, analog voltage regulation and temperature control |

|

Vacuum State |

Matching Large or Small Secondary Vacuum |

|

Upper Frame Structure |

It can be adjusted arbitrarily according to the different mold sizes |

|

Sheet Conveying |

Manual Placement |

|

Product Demoulding and Pick-up |

Air Pressure Blowback Demoulding |

|

Other Functions |

Bubble Blowing, Anti-sag, Large and Small Vacuum |

|

Adaptable Processing Materials |

PP. PC. PE. PVC. ABS. PS and other thermoplastic sheets |

|

Machine Dimension |

3800mm*4600mm*3200mm (excluding the upper mold) |